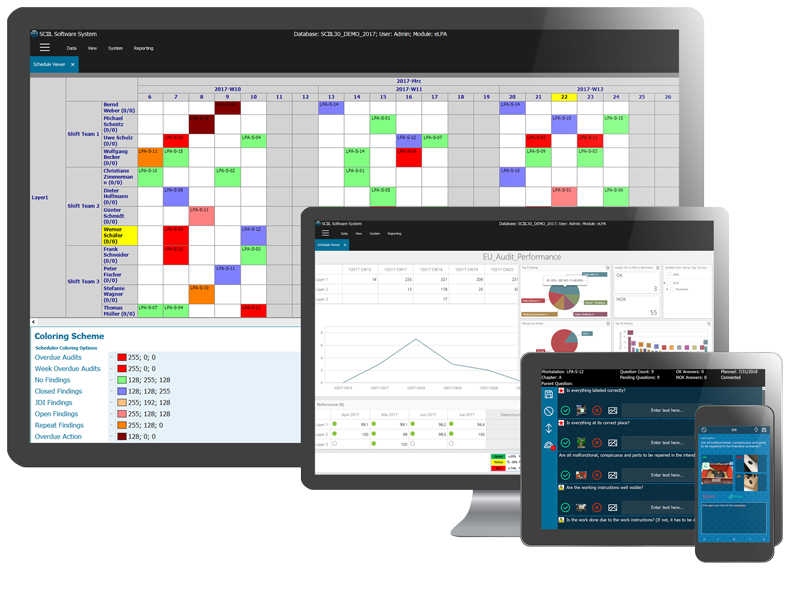

Mühlacker, Germany - A first-class product quality is easier to achieve if the proprietary processes function smoothly. Layered process audits are a proven tool for verifying the consistent implementation of process standards. But what can be done if there is already a sticking point in the process for controlling the processes?

An Interview with Daniel Zimmermann from MAHLE Behr GmbH & Co. KG, Head of Quality Management at the plant in Mühlacker.

An Interview with Daniel Zimmermann from MAHLE Behr GmbH & Co. KG, Head of Quality Management at the plant in Mühlacker.